|

|

|

|

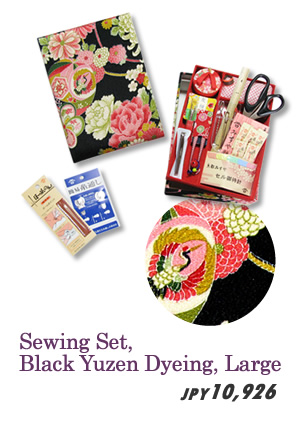

Misuya Chuubei is a needle shop that has been operating in the Matsubara district of Japan's traditional capital, Kyoto, since 1819. Its artisans create Misuya needles using the same closely guarded techniques that have been employed since the Edo era, but improved over time as new ideas develop. Today there are very few shops that bear the Misuya needle mark, but Misuya Chuubei continues to be patronized by both professionals and regular hobbyists. Traditionally, most clothes, ranging from the everyday clothes of normal people, through to their special outfits, and all the way up to the spectacular apparel of the aristocracy, were made with these needles. These demands were many. They had to ease the strain on the tailors and be easy to work with, they had to be strong and resistant to bending or breaking, and not only could they not damage the material they were being used with, they had to in fact highlight its qualities--such as luster, pattern and feel. If any of these demands were not met, they would frustrate the tailors and ruin the wearer's hopes to look their best. There may be many who think needles are just needles, but Chuubei did not think that way, and held these qualities to be of vital importance in making theirs. Respecting and upholding tradition while adopting new ideas to create the best needles. We here present needles for all sorts of sewing, each designed specially for their purpose. Sewing with a fine needle is relaxing, and these needles are certainly that. |

|

|

|

|

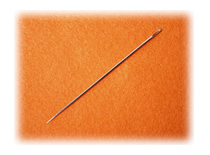

Needles are made of steel. But if a sewing needle made of this famously hard material is just hard, it will not satisfy. For the smooth passage of a needle when sewing, it must also be flexible. But as well as being flexible, it must also have a strong core; if it does not, it will break or bend and become difficult to sew with. Hardness is prone to being brittle; softness is prone to bending. Combining these two seemingly contradictory properties is a very difficult task. Techniques that make it possible have been added over time to the tempering process, which is still used today. |

|

|

|

The eyes of Misuya needles are made as close as possible to perfect circles. Answering the challenge of how large a hole can be made in the thin body of a needle is one of the times at which a maker of needles shows their worth. The small hole is then polished and made smoother. |

|

|

|

The best shape for a needle is one that gradually and smoothly becomes thinner from the eye to the point. If the point becomes sharp too suddenly, the material will resist the needle's passage and risks being damaged. A needle that gradually becomes thinner almost eliminates the resistance of the material, enabling smooth stitching. |

|

|

|

One important stage of making a needle is the polishing of the surface. Today the standard polishing method is a widthways polish, but Misuya needles use a lengthways polish. Widthways polishing can be effectively performed by rollers, but because it occurs perpendicular to the needle's passage through the material it increases resistance. In contrast, Chuubei's lengthways polishing produces lines so fine they cannot be seen with the naked eye, running in the same direction as the needle moves. These grooves act as guides when the needle passes through the fabric, enabling an even smoother passage. But if the grooves are large enough that they can be seen with the eye then the needle will not perform well. Nor will it perform well if the polishing is uneven. In order to achieve an even finish that does not distort the shape of the needle, a polish even on the scale of 0.001 millimeters is required. The polishing stage is a point where even long-experienced artisans nervously hold their breaths. |

|

|

|

Even the final stage--the wrapping of the needles--occurs under the watchful eye of a human. Before wrapping, the quality of the forging and finish of each needle is checked one by one. A needle that is believed to have the potential to cause damage when used to sew is removed, so you can use each of the 25 needles contained in each pack with confidence. The wrapping is designed to protect the needles, so it features aluminum foil that prevents the buildup of humidity. It is also bears Chuubei's mark. |

|

|

|

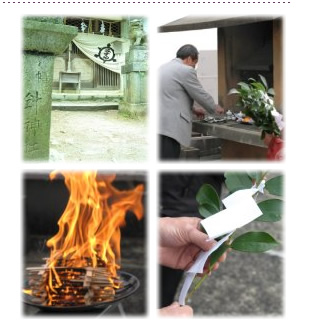

Every year on December 8, Misuya Chuubei holds a needle memorial service. This is to express thanks to those needles that have bent, broken, or otherwise outlived their usefulness, and to pray for an improvement in skill with needles in the coming year. If you have a needle that you ordered from JSHOPPERS.com but have now retired from use, you may send it back to us and we will hold a memorial service for it. (Needles must be received by November 30.) |